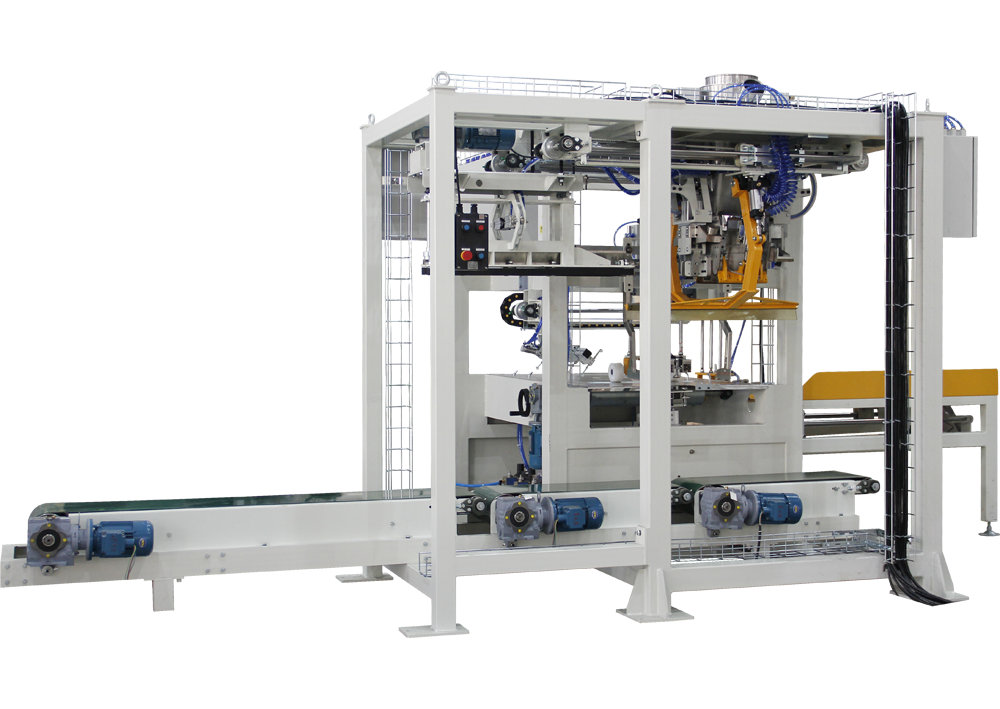

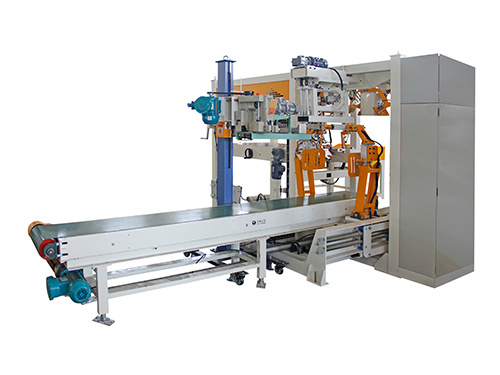

Batching system

Batching scales are widely used in flour, feed, pharmaceutical, metallurgy, food, chemical and other industries of different kinds of materials ingredients and mixing operations. The batching scale has a reasonable structure and consists of a feeding auger, a feeding port, a scale body, etc. The feeding port is combined into a whole by soft connection and feeding equipment to form a closed combination. The device has a standard communication interface and a variety of recording functions, print real-time reports and a variety of records. Data information reports such as shift production, daily production and monthly production can be output. The operation interface of the batching scale has; It can be operated in conjunction with the upper computer, and all Chinese functional dishes are used when the upper computer is operated.

Key words:

Semi-automatic packaging scale, automatic packaging system, intelligent conveying and palletizing system

Classification:

Powder blending engineering

Hotline:

Batching system

1. Structural characteristics

Batching scales are widely used in flour, feed, pharmaceutical, metallurgy, food, chemical and other industries of different kinds of materials ingredients and mixing operations. The batching scale has a reasonable structure and consists of a feeding auger, a feeding port, a scale body, etc. The feeding port is combined into a whole by soft connection and feeding equipment to form a closed combination.

The device has a standard communication interface and a variety of recording functions, print real-time reports and a variety of records. Data information reports such as shift production, daily production and monthly production can be output. The operation interface of the batching scale has; It can cooperate with the upper computer to operate, and all the operation steps are prompted by the Chinese function menu during the operation of the upper computer. The operation interface can display process flow chart, formula number, formula weight, actual ingredient weight, ingredient error, mixing time, trace addition prompt and reply, equipment operation status, fault information, etc.

2. Technical parameters

1, Accuracy: ± 0.3%.

2, weighing range: 3-6 tons/hour

3, conical barrel type weighing bucket, no hanging material sticky material phenomenon (optional vibration air hammer)

4, three-point balanced weighing sensor weighing structure

5, support up to six feeding auger at the same time feeding

6, used in conjunction with the mixer

Related Products

online message