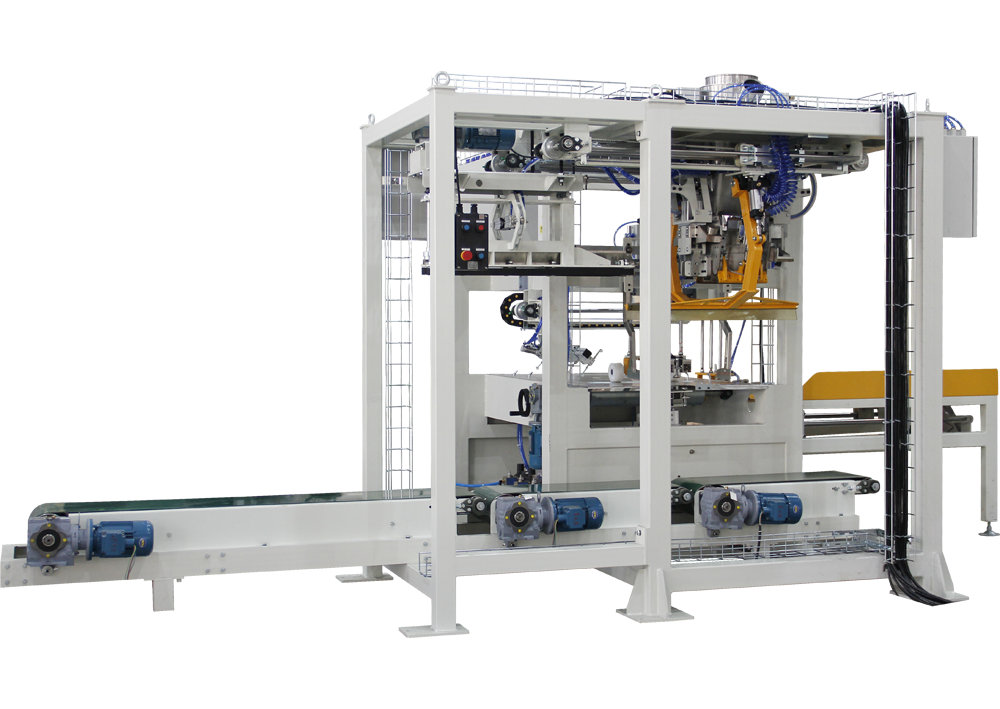

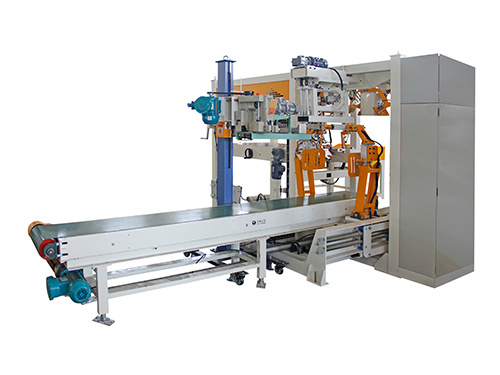

Fully automatic packaging system

Bagging speed: 200-250 bags/hour Weight range: 25-50kg Measurement accuracy: 0.2% Applicable materials: starch, flour, additives and other granular materials Packing bag form: kraft paper bag, laminated woven bag, etc Bag supply mode: bag warehouse switching, circulating bag supply On the bag way: support bag type Supporting equipment: bag holding device, air extraction system

Key words:

Semi-automatic packaging scale, automatic packaging system, intelligent conveying and palletizing system

Classification:

Fully automatic packaging system

Hotline:

Fully automatic packaging system

After adopting the suction type automatic bagging quantitative packaging system, the whole production line can realize the fully automatic process of automatic weighing, automatic unloading, automatic air extraction, automatic bag suction, automatic bagging and automatic bag feeding (bag moving and conveying). After each action of each station in the automatic bagging unit is completed, the next same action can be carried out. The control system automatically judges whether the action of each station is successfully completed. Each part is equipped with a control safety interlocking device, to achieve continuous operation, as far as possible to adapt to high-speed continuous operation, greatly saving the number of operators, for the enterprise to save considerable labor costs.

Bagging speed: 200-250 bags/hour

Weight range: 25-50kg

Measurement accuracy: 0.2%

Applicable materials: starch, flour, additives and other granular materials

Packing bag form: kraft paper bag, laminated woven bag, etc

Bag supply mode: bag warehouse switching, circulating bag supply

On the bag way: support bag type

Supporting equipment: bag holding device, air extraction system

Related Products

online message