High efficiency, low energy consumption, intelligent

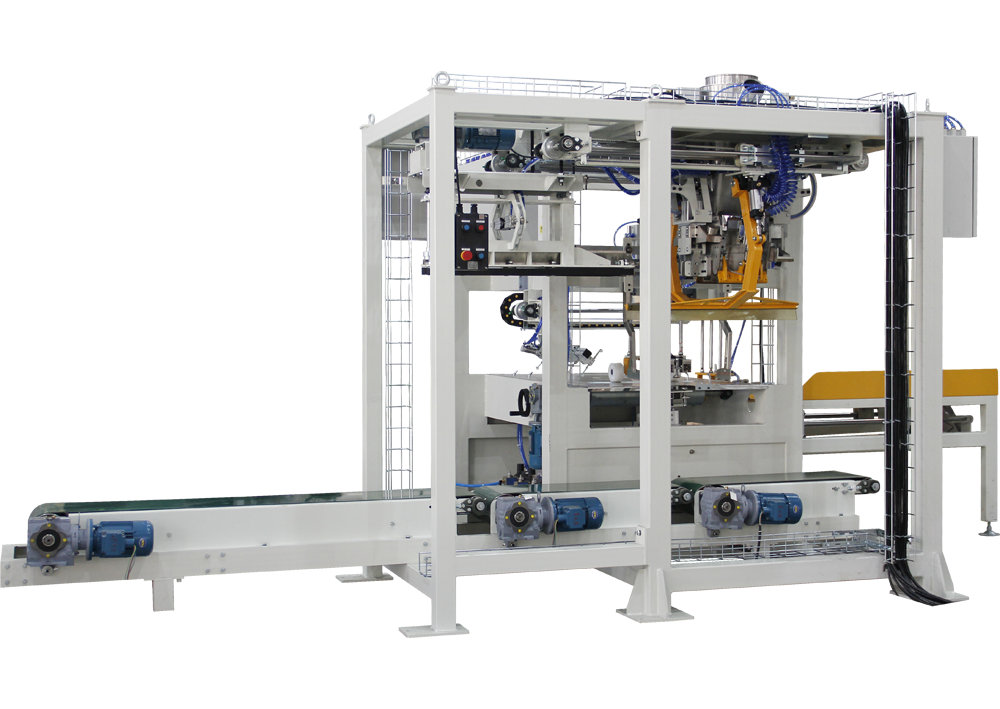

The advanced automatic palletizing production line starts from the suction packing scale and takes the robot palletizing as the terminal.

Save labor costs, the whole process only need two people to operate, save labor.

Automatic inverted bag lying flat device, flattening machine, metal detector, recheck scale, automatic rejection machine and other process control equipment.

Install multiple input detection signal, foreign matter, overload, rejection and other alarm indication units

A variety of palletizing position stacking methods, with different packaging weight, at the same time to meet the maximum three incoming channels

From 600 packages to 1200 packages, to meet your different capacity needs, up to 1600 packages

Multi-function touch screen graphical operation interface, the whole production line is fully automatic controlled by PLC,

Through the touch-type man-machine interface, the palletizing data can be generated by inputting the information parameters of each palletizing position.

Three kinds of teaching method, the most simple and intuitive manual teaching

Graphical programming, flexible programming, according to the actual situation of each enterprise

Technical characteristics and parameters of palletizing robot

Robot model: EC151,EC-171,EC201

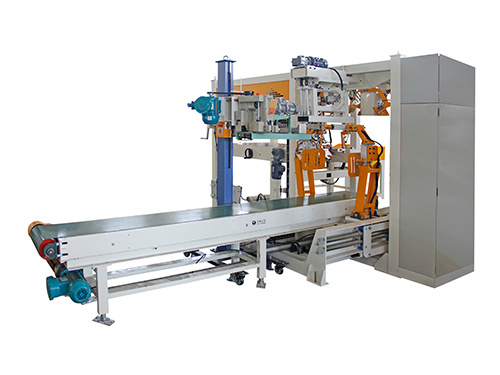

Mechanical structure: multi joint palletizing robot

Robot action mode: cylinder coordinate type

Palletizing weight: 110kg

Robot palletizing capacity: 600-1200 c/hr

Action axis: standard four axis

Robot gripper: splint, claw, suction cup, etc.

Palletizing memory capacity: standard 30, (up to 400)

Teaching method: manual teaching/teaching support/teaching exemption

Power supply: 3KVA 200V 3PH 50Hz

Working compressed air: 0.5Mpa

Power consumption: 1.9KVA-6.5KVA

Robot body weight: 750kg

Space requirements: the palletizing robot arm can be set in a narrow space, the site use efficiency is high, the application is flexible.

Motion characteristics: multi-directional linear motion, driven by servo motor, linkage mechanism, few parts, transmission efficiency up to 96%.

Stacking repeat accuracy: ± 0.5mm, and in the case of high-speed operation, the mechanical arm will not appear shaking, noise and other abnormal conditions.